Introduction

Ever wonder how a home can be built inside a factory and delivered to your land in a single day?

Welcome to the world of modular homes in California, where innovation, precision, and efficiency come together to create your dream home faster and smarter than traditional methods.

At Cutting Edge Homes, we specialize in guiding you through the entire process, from factory construction to on-site setup. Every home is built to the same building codes as site-built homes, ensuring quality, safety, and longevity while avoiding many of the delays and surprises that come with traditional home building.

In this post, we’ll walk you through exactly how our modular buildings are constructed, delivered, and installed, step-by-step, so you know what to expect and why this innovative approach to construction methods works so well for California properties.

Step 1 – Precision-Built in the Factory

All of our homes begin life in a controlled factory environment, not on a muddy construction site. This controlled setting protects your home from weather, theft, or construction delays, which are common with site-built or stick-built homes.

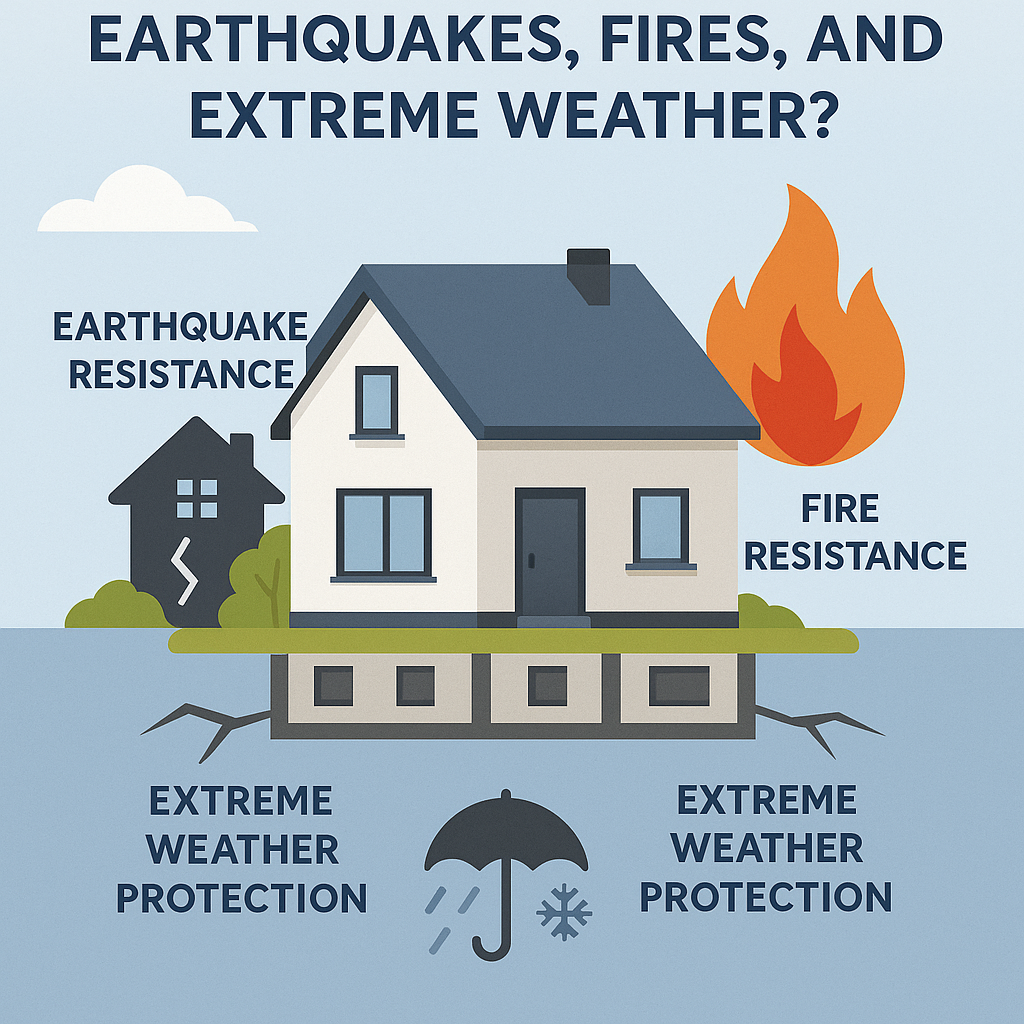

The home’s modules are constructed indoors using high-quality materials and the same standards required by local building codes. In fact, modular homes must meet or exceed the California building codes used for single-family dwellings and accessory dwelling units (ADUs).

This factory-built housing process ensures your home is not only built faster but also in a more cost-efficient, energy-efficient, and eco-friendly way; one of the many advantages of working with trusted modular home manufacturers like CEH.

Step 2 – Rigorous Quality Checks at Every Stage

Inside the factory, we use a high degree of precision and strict quality control checks at every stage of the modular construction process. Every wall, floor, ceiling, and system is tested multiple times to ensure structural integrity and performance.

Our team ensures every modular home we build is compliant with building codes and California-specific safety requirements. Unlike some manufactured homes or mobile homes built under HUD code, our modular homes are constructed to meet the International Residential Code (IRC), just like site-built homes.

This gives homeowners peace of mind knowing their new home is held to the same building codes and even exceeds them in many cases.

Step 3 – Preparing the Site for Delivery

While your home is being built in the factory, we’re also helping you prepare the building site. This includes site prep like grading, utility setup, driveway access, and preparing the permanent foundation, all crucial steps for smooth delivery.

Whether you’re building on private property or in an urban lot, CEH ensures that everything is ready for your home’s arrival. We also assist with permits, construction loans, and connecting with a trusted general contractor if needed.

This dual-track approach, building off-site while prepping on-site, is what helps modular homes save time and avoid construction delays.

Step 4 – Coordinated Transport Across California

Once your modules are finished, it’s time for one of the most exciting moments: modular home delivery California style.

Each section of your home is loaded onto special trucks and carefully transported to your property. This isn’t your average delivery — it involves detailed planning around traffic, road width, and clearance. We work with transportation experts and local agencies to ensure your home arrives safely and on schedule.

Our team oversees every detail, from loading to arrival, so you don’t have to stress about logistics.

“It’s not just about getting the home there, it’s about making sure everything goes right, down to the last mile.” — Isaac Lassiter, President of Cutting Edge Homes

Step 5 – Crane Day: Assembly On-Site

This is what we call the modular home setup day, and it’s incredible to watch.

A professional crane lifts each module and sets it into place on your foundation with impressive precision. Walls, rooms, and entire floors come together like giant puzzle pieces, often within just a few hours.

Because the modules are already finished inside, including drywall, cabinets, and flooring, the assembly process is fast and clean. This method helps avoid other obstacles common in traditional homes, such as framing errors or weather-related delays.

Want to see it in action? Check out our Gallery (link to gallery)

Step 6 – Final Touches & Walkthrough

After crane day, we connect everything, plumbing, electrical, air conditioning, solar panels, and other finishing details. We inspect every inch, complete a final walkthrough with you, and answer all questions.

Your CEH project manager ensures your home design, layout, and finishes align with your personal needs, vision, and expectations. And remember: every CEH home is designed to be your primary residence, not a temporary structure.

Our homes are not kit homes; they are high-end, custom-crafted modular housing options built for real life and long-term value.

Conclusion: Built with Care, Delivered with Confidence

The modular home construction process is more advanced, efficient, and rewarding than many people realize. At Cutting Edge Homes, we manage every part of the journey — from factory setting to site prep, from transport to your final dream home.

Here’s why families across California are choosing to build modular:

- Built in a controlled environment

- Fewer construction delays and less waste

- Compliant with local building codes and IRC

- Fully customizable to meet your personal needs

- Faster move-in without sacrificing quality

Want to see what your factory-built future could look like? Browse our gallery or contact us to get started